The Production Process and Characteristics of Honkaku Shochu

Honkaku Shochu is a traditional Japanese distilled spirit, with its production methods refined over centuries. The production process comprises five main steps: raw material preparation, primary mash (moromi), secondary mash, distillation, and post-processing. Each stage relies heavily on the expertise and knowledge of the master brewer (toji).

1.Raw Material Preparation

In the raw material preparation stage, rice is polished and washed. The rice is carefully rinsed with water and soaked for a specific period to achieve the desired moisture content. Excess water is drained, and the rice is steamed for about an hour to achieve the optimal texture and moisture levels. After steaming, the rice is cooled to an appropriate temperature.

2.Primary Mash Production (Koji Making)

The primary mash production begins with koji making, the most critical step in this stage. Steamed rice is inoculated with koji mold, and the temperature and humidity are carefully controlled for 36 to 48 hours. The ideal temperature for cultivation is 30–32°C, with humidity maintained at approximately 90%. During this process, the koji mold produces enzymes that convert starches into fermentable sugars.Typically, yellow koji mold is used for shochu, but black or white koji molds may also be employed. The type of mold used significantly impacts the flavor and characteristics of the final product.

3.Secondary Mash Production

Secondary mash production begins by combining the primary mash with water and yeast to initiate fermentation, which is monitored over two to three days. The primary mash is then mixed with additional main ingredients and water in fermentation tanks, where it ferments for approximately two weeks at around 25°C.Temperature management is crucial during fermentation. The progress is checked daily, monitoring alcohol content, acidity, and changes in aroma and flavor.

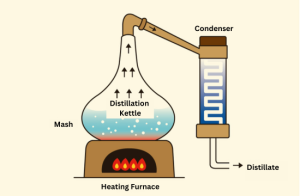

4.Distillation

Honkaku Shochu is distilled using the traditional single distillation method. By distilling the mash only once, the process preserves the characteristics and aromas of the raw materials. Precise temperature control is essential during distillation, and the output is divided into three stages: the initial run, the main body, and the final run. Only the main body is used as the product. The typical alcohol content is 35–45%.In recent years, vacuum distillation has also been introduced. This method allows for distillation at lower temperatures than atmospheric distillation, resulting in smoother, less astringent shochu.

5.Post-Processing

In the post-processing stage, the distilled liquid is first aged in tanks or barrels for a minimum of one to two months. The alcohol content is then adjusted to match the product's characteristics, often through dilution with water.Finally, filtration processes, such as activated charcoal filtration, are used to remove impurities and enhance the clarity of the product. This stage significantly impacts the quality of the finished shochu.

6.Quality Control in Production

Quality control involves testing alcohol content, aromatic components, acidity, flavor, and color. Sensory evaluations by experienced master brewers are particularly important to assess the overall taste and aroma.Temperature and hygiene management are vital throughout production. This includes maintaining optimal temperatures during each stage, adjusting for seasonal variations, and ensuring cleanliness of equipment, workspaces, and personnel.

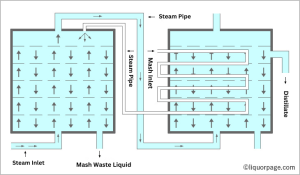

7.Differences Between Honkaku Shochu and Ko-Rui Shochu

The primary distinction between honkaku shochu and ko-rui shochu lies in their distillation methods. Honkaku shochu uses single distillation to retain the characteristics of the raw ingredients, while ko-rui shochu employs continuous distillation for a neutral flavor profile. Understanding these differences is key to appreciating the diversity of Japanese distilled spirits.

Characteristics of Single and Continuous Distillation

Shochu is broadly classified into two types based on its distillation method: Single Distillation Shochu (Honkaku Shochu) and Continuous Distillation Shochu (Ko-rui Shochu). Each method has distinct characteristics that significantly influence the flavor and production efficiency of shochu. Below is a detailed explanation of their differences: